WHY CHOOSE ALLSKU FOR YOUR INVENTORY REPLENISHMENT?

-

Boost Sales – Capture every opportunity with the right products in stock.

-

Exceed Service Expectations – Deliver on promises and build long-term customer loyalty.

-

Eliminate Stock-Outs – Keep shelves stocked and orders flowing smoothly.

-

Increase Fill Rates – Achieve higher fulfillment accuracy and earn customer confidence.

-

Gain Actionable Insights – Leverage real-time data to make smarter inventory decisions.

-

Reduce Excess Inventory – Unlock working capital and minimize storage needs.

-

Accelerate Turnover – Move inventory faster to strengthen cash flow.

-

Cut Shipping Costs – Eliminate costly last-minute freight expenses.

-

Improve Productivity – Streamline processes across your supply chain.

-

Save Planning Time – Automate replenishment and free your team from manual calculations.

CLARIFY THE FUTURE

Allsku is designed for organizations that issue recurring SKU-specific purchase orders and wish to maintain optimal inventory levels by ensuring the right products, are at the right locations, in the right quantities, at the right time, and at the right cost. Any deviation from these principles undermines the value of the inventory.

Allsku has developed a service that allows e-tailers, e-commerce platforms, retailers, wholesalers, distributors, manufacturers, medical facilities, government entities, and hospitality organizations to gain a unified understanding of their inventory replenishment needs. This ensures they have the necessary data to plan and act accordingly.

We take your data and bring clarity, with unparalleled detail and insight, so you can be confident that your next inventory planning decision will be fully optimized.

WHAT WE DO

Allsku supplies organizations with optimal inventory planning parameters that help maximize their supply chain efficiency.

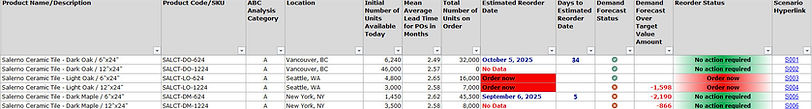

Using your demand forecast and other pertinent data, the current and future scenario is identified, indicating when a new order should be placed to achieve and then maintain a specified inventory service level at any of your locations. Six months of visibility is displayed.

The majority of our clients compile their own in-house demand forecasts and others use third-party options. Before they came to us, all had one thing in common – they had no clearly defined technique of how to use their demand forecasts effectively, to attain an optimized inventory plan.

COHERENT INVENTORY PLANNING

Dynamically calculates optimal stock levels and precise reorder dates.

OUTSTANDING METHODOLOGY

Our inventory planning algorithm integrates the initial available quantity of stock, the number of units sold in the current month, all orders in transit, historical lead times, monthly demand forecasts with each ± percent error, and service level requirements for each month, to calculate when a SKU will fall below the automatically generated safety stock threshold and extrapolates the date, at which an order will need to be placed, to retain the appropriate stock level.

This is a unique approach that circumvents the reorder point theory and replaces it with the reorder date system, where the projection for a specific day to reorder is calculated. Distinct from the reorder point theory, our approach is able to accept long and/or inconsistent lead times, variability in the monthly demand forecasts, and multiple replenishment orders that are already in transit, ensuring that the results are always optimized. We have also included a module for those clients who prefer utilizing cyclical reviews (order-up-to level), which specifies the amount needed to take the inventory level to the optimal maximum.

Our methodology is engineered to deliver a comprehensive operational transformation. By moving beyond traditional guesswork, our clients achieve a powerful interaction of financial and performance-based gains, all while enhancing their team's strategic capabilities.

This approach directly mitigates critical business risks. Having insufficient stock disappoints customers, leading to eroded loyalty, higher attrition rates, and ultimately, sending new customers directly to your competition. Furthermore, stock-outs catastrophically interrupt cash flow and often create costly production or procurement backlogs, hampering overall growth.

Instead, our system delivers a direct and measurable impact on your bottom line and operational health:

-

Superior Customer Performance: Dramatically improve product availability and service levels, leading to higher line item fill rates and increased customer satisfaction.

-

Optimized Financial Efficiency: Significantly reduce capital tied up in stock, lowering overall inventory costs and carrying fees, while simultaneously improving inventory turnover rates.

-

Enhanced Operational Productivity: Free your team from manual calculations - Streamlined processes lead to enhanced operational efficiency, allowing your employees to focus on strategic growth instead of daily stock management.

In essence, we replace the costly cycle of reactive inventory management—and the severe risks of stock-outs—with a precise, proactive strategy that drives performance and protects revenue across your entire organization.

HOW OUR SERVICE WORKS

At your chosen intervals (or whenever vital numbers change), you provide your data using our Excel template. The data is then processed through our algorithm and your results are compiled, in Excel, in one (or more) batches, which will be returned by email as an attachment.

We have created Allsku to be the most accurate, straightforward, cost-effective, and easy to implement inventory replenishment service available. All that's needed is that you are able to extract your data and save it in Excel.

Our comprehensive package contains a detailed results index page with hyperlinks to each corresponding SKU/location sheet. Each batch has up to 192 scenarios.

Our pricing structure is simple and straightforward. It's pay-as-you-go. There's no contract to sign and no hidden fees.

THE STRATEGIC ADVANTAGE

Turn Your Largest Operational Challenge into Your Greatest Competitive Edge.

For businesses with complex supply chains and long lead times, inventory is a constant high-stakes balancing act. You’re caught between two conflicting goals: minimizing capital tied up in stock and maximizing product availability to prevent costly stockouts.

Traditional forecasting often fails, treating estimates as certainties and leaving you vulnerable to real-world volatility.

Allsku changes the game. Our specialized methodology uses probabilistic forecasting to actively model the inherent uncertainty in both demand forecasts and supplier lead times. This allows us to move beyond guesswork and scientifically calculate the optimal order dates and quantities for every single SKU in your portfolio.

The Result? Inventory transforms from a costly, reactive burden into a strategically managed asset.

-

Estimated reorder date is identified and the number of days to that date is displayed

-

Service level requirement can be set to a user-defined value for each month

-

Demand forecast ± percent error can be set to a user-defined value for each month

-

Safety stock level is automatically calculated to daily values

-

Stock projection graph is fully dynamic and will show up to 6 months of data

-

Economic Order Quantity (EOQ) can be calculated and optimized for next submission

-

Demand forecast values are checked to confirm that targets are attainable

Ready to stop guessing and start optimizing? Contact us below for a free consultation.